Availability: In Stock

Features :

Higher Capacity

The evolutionary integration of technolgies by Satake has resulted in a system which presents paddy to the husker rolls in the best possible orientation and at the highest practical feed rate for the variety of rice being husked.

Reduced Brokens

In plant testing of the new husker has proven a significant reduction in the level of brokens generated during the husking process.

Automatic Operation

A level gauge monitors paddy being fed into the husker inlet and activates an air cylinder which opens the shutter and feeds the paddy into the husking chamber. The pneumatic control system maintains a constant pressure between the rubber rolls, which helps to ensure a uniform husking ration.

Rubber Roll Life

Satake’s unique feeding system, coupled with its precise control system, greatly enhances the efficiency of the husking process. Initial testing indicates increase in roll life by 30% or more.

New Design

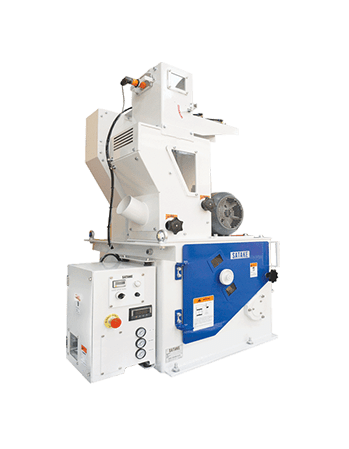

The roll housing has been moved forward on the frame to facilitate operator access when changing rubber rolls.

| Tipe | HU10RH-T |

|---|---|

| Daya (kW) | 7,5 |

| Kapasitas (rpm) | 3,5 – 5,5 |

| Kecepatan poros (rpm) | 1200 |

| Ukuran rubber roll (inch) | 10 |

| Berat (kg) | 572 |

Reviews

There are no reviews yet.